Campervan fitout

Quality contract cutting

Our name says it all. Cutting to size and shape all manner of materials including solid wood, wood composites, acrylics, aluminium & polystyrene. This is done by a state-of-the-art robotic Thermwood CNC router. Edge-banding, drilling and hardware are complementary to the cutting service.

Cabinetry cut to size with our premium CNC router cutting services

Measure twice, cut once. But with only 24 hours in a day, it can be difficult for kitchen designers, cabinet makers, shopfitters or furniture creators to achieve precision cuts while still meeting deadlines and managing growing job lists.

You need the power of a factory behind you with the capacity to support jobs you can’t quite complete yourself, or to take care of all the manufacturing if you don’t want to fund and manage equipment, premises, and employ extra people.

Help Keep Wheels Rolling

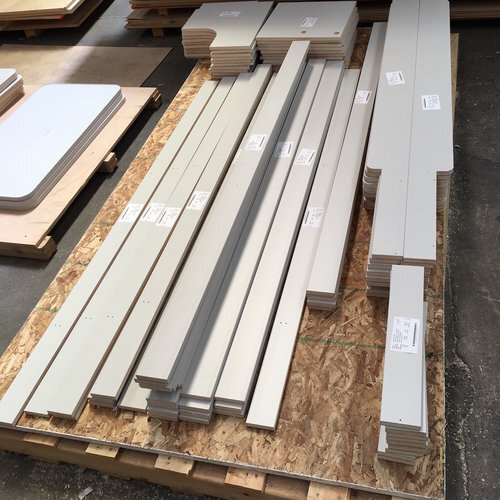

When you’re building up a fleet of campervans, you want them all on the road at the start of summer, so new vehicle fit-outs have to be turned around fast. Cutshop® Waikato has recently been working hard to cut and assemble cabinets for 50 campervans over a period of eight weeks.

Cutshop® Waikato got the job because they provided scalability and could handle short lead times.

Each campervan needed cabinetry for the kitchenette to house the sink including storage underneath, plus cabinets for the microwave and small fridge. Two long bed units with storage compartments underneath also had to be cut for each vehicle.

It’s a very seasonal job. The customer supplies the vehicles and we fit them out. On this recent job the customer got the vehicles to us later than planned. When the order came in for the first 20 vans, Cutshop® stepped up. By working extra hours and bringing in temporary staff to handle assembly, there was soon a stack of 20 sets of units waiting in the warehouse — rather than a production queue.

The client had originally planned to assemble the units but found themselves short-staffed with a deadline looming.

“We didn’t have the time to put them together, so it was handy that Cutshop® could do it. Convenience is a big thing for us. Cutshop® are really easy to deal with, they’re very friendly guys. We’ve put a bit of pressure on them at times and they’ve done well. Given the quantities involved in this job, it needed to be done using a CNC machine to handle the volume and repeatability. Cutshop® always deliver a nice, tidy job. The flow-through has been much easier – and that keeps our customer happy.”

The cabinetry is built using soft plywood (a third of the weight of standard ply) coated with a high-pressure laminate to ensure integrity. The cabinets need to be lightweight to avoid increasing vehicle fuel consumption. The client supplied the board and Cutshop® supplied the trim.

It’s been a great job for us,” comments Keith Hofer, business owner at Cutshop® Waikato. We can easily customise cabinetry for a specific space and are set up with the machinery to handle volume. We’re looking forward to more motorhomes in 2018.”