Fits the bill.

Cutshop® ‘factory in your back pocket’ fits the bill for Apex Interiors.

With a high-profile portfolio of successful fit-outs for national retail chains and feature ceiling installs for clients like BDO Spicers and Telecom Towers in Auckland’s CBD, there are good reasons why the award-winning team at Apex Interiors continues to go from strength to strength.

The team at Cutshop®, Mt Wellington has been working closely with Apex directors Chris Bamforth and Shannon Irvine from the very beginning.

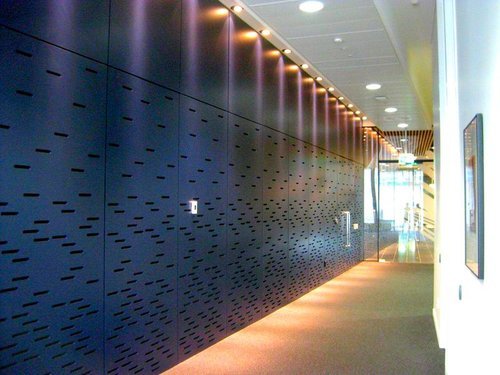

Over the past eight years Cutshop® has cut, labelled and packed MDF and timber pieces for a wide range of jobs; most recently a complex fit-out at Auckland International Airport.

“The end-product is always cut correctly to the millimeter. We’ve never had a problem with faulty product – the only error in dimensions over the past eight years has come from our end!

The architect draws it, we work out how to build it and Cutshop® cuts the templates to form the base structure from the CAD plans.”

Apex directors value Cutshop® ability to up- and downscale according to the size of the job in hand – from creating some bespoke display cabinets to precision-cutting templates made from curved pieces of MDF/timber to form the structure for feature ceilings.

Cutshop® have three large flatbed CNC’s in New Zealand, one at each branch. This means that Cutshop® can use the largest sized sheets of solid wood, composites like MDF, acrylics, aluminum and even polystyrene for moldings and signage. Templates can be cut in a way that makes the best use of the material with less wastage, which keeps costs down.

“For large projects, all the pieces have to be cut, labelled and packed correctly, or it would be a nightmare to install. Shane at Cutshop® Mt Wellington takes care of that and then we lay them out and put them together on-site like a massive jigsaw.

Some jobs have 20 to 30 pieces that make up a feature ceiling – and the pieces can all be one radius or 20 different radiuses to form wave patterns. It can be quite complex.”

It wouldn’t be cost-effective to own that kind of machinery and cut the pieces ourselves.

This efficiency pays off when it comes to meeting deadlines. The Apex team can have anything from two weeks to several months to complete a job. “Cutshop® is very reliable and they turn jobs around very quickly – in four to five days. They can take on any sized project.”

Apex is currently working at the International terminal at Auckland Airport putting up ceilings in three duty free stores. In order to accelerate the project, the teams are working 24-hour shifts. The whole job needs to be completed in three months – with only six weeks to fit all three ceilings.

“It wouldn’t be cost-effective to own that kind of machinery and cut the pieces ourselves. Cutshop® provide the factory and we focus on getting it right on-site. In the early days, we used to hand cut some jobs but you just can’t match the accuracy that we get from Cutshop® – there’s always human error.”

“Even if we’re involved with a smaller job that needs something a little different, Simon is very helpful. He inputs into design ideas and material options to make the end-product as attractive as possible for the client. Cutshop® can also do 3D modelling of the product so that we can see what it will look like.”

18 months ago, Apex Interiors opened two new branches. Another is due to open this month and there’s one more in the pipeline. Their Hamilton team has already been to meet the local Cutshop® people with the aim of setting up another successful partnership. “Cutshop® really acts like an extension of our own team,” said Chris